Resource

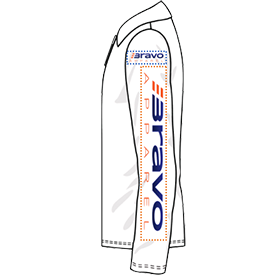

Where can you do embroidery on your shirt?

Nothing beats the quality feel of classic needlework. Created by using a special machine that is programmed to stitch a design that combines texture, pattern and color. We take pride in our embroidery and digitization services. Bravo Apparel offers the very latest in embroidery techniques and threads that add dimension to the design and enable logos to stand out.

Front example

Back example

Side example

What is “Halftone Printing”?

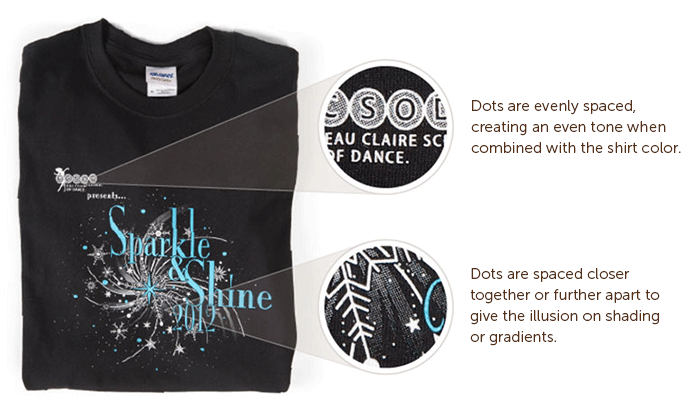

Halftone is the graphic technique that simulates shading through the use of dots. Halftone prints are commonly used in newspapers to blend colors, and in screen printing it’s a similar process. We use this technique to print photographic or otherwise multi-tonal artwork using only one ink color, which can often significantly reduce order costs.

If you are looking to print a photograph on a tight budget, a monotone halftone print is the best option! Using halftone printing (similar to newspaper print, with dots of ink closer or further apart to create an image), we can print on any color shirt, although light fabric with dark ink produce a more attractive result.

Halftone printing also works well if the original image is smaller or of a lower image resolution, since halftone printing does not have the same level of detail as a process print.

As a general rule of screen printing, halftones usually look best when the ink being used is darker than the shirt (for example, black ink on a white shirt) but our production team will work to ensure you receive the best print possible no matter what color combination you choose.

In order to print a photograph in halftones, we need to have a high resolution photo. Please ensure you’re providing the best available version. Also, while we do our best to show you the most accurate picture proof possible, we cannot recreate halftone effects in our proof images. Please reference the example images to get a better idea of what halftones will look like on your printed product.

In order to print a photograph in halftones, we need to have a high resolution photo. Please ensure you’re providing the best available version. Also, while we do our best to show you the most accurate picture proof possible, we cannot recreate halftone effects in our proof images. Please reference the example images to get a better idea of what halftones will look like on your printed product.

What is “Heat Transfer”?

Bravo Apparel offers heat transfer embellishment solution for your logo or unique design. This digital printing process, which utilizes high temperature to transfer and adhere your design to the fabric surface uses many of the same inks and techniques that are used in printing.

This is a highly cost effective decoration technique for low minimum orders with a short turnaround.

What is “Sublimation”?

From simple logo placement to stunning graphics with photorealistic details, dye sublimation is ideal for team uniforms and promotional apparel made with polyester fabrics.

Sublimated designs last longer than scree printed designs. Logo and artworks won’t fade or crack because sublimation ink chemically bonds with the fabric and actually becomes part of the garment when heated.

Screen Printing vs. Digital Printing

Bravo offers two different methods of printing, in order to provide a process that best suits your artwork. We offer traditional screen printing for the majority of our products, as well as digital printing on selected items. Screen printing involves creating a stencil (printers call this a “screen”), and then using that stencil to apply layers of ink on the printing surface. Each color is applied using a different stencil, one at a time, combined to achieve the final look.

Digital printing is a much newer process that involves your artwork being processed by a computer, and then printed directly onto the surface of your product. Digital printing is not a heat transfer as the ink is directly adhered to the fabric of your shirt. Each printing process has its strengths, and our artwork team will weigh these when deciding which to use for your design.

Screen Printing

Screen printing is the best option for designs that require a high level of vibrancy, when printing on dark shirts, or for specialty products. The ink in screen printing is applied thicker than digital printing, which results in brighter colors even on darker shirts. The fact that these products are printed by hand also allows for unique products like water bottles, koozies and mugs, as the printer can manually handle curved or uneven surfaces. The minimum order quantity on screen printed items exists because of the extra materials and labor time associated with this printing method.

Digital Printing

Digital printing is best used for items that require high amounts of detail, and orders of a smaller quantity. The fact that the digital printer does not use screens allows for a photographic print, with much more detail than traditional screen printing. As the ink is applied thinner (to achieve such detail), digital printing is best used on lighter colored shirts to allow the design to shine through. The fact that the design is processed and printed digitally allows for a quantity of one, since there are no screens or physical setup.

At Bravo we are proud to stand behind each printing method, 100% of the time. While we are currently working to enable more products for digital printing, the products available on the website have been thoroughly tested and approved. We are printing perfectionists, and will not enable products for either method that do not result in the best final product. Artwork printed by both methods goes through the same process of being reviewed and proofed by our product experts.

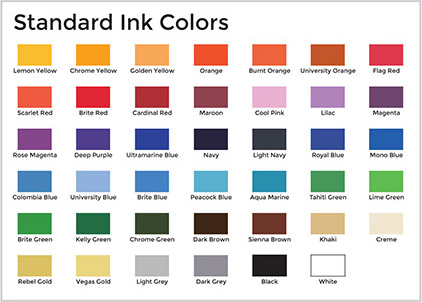

Matching your ink colors

We can match your logo/artwork color(s) to a Pantone color(s) that will contrast well with your chosen product. Our product experts will take the time to go over your design and help you choose the best color for your needs. Please note that there may or may not be a small fee for this service, depending on the size of your order.

To request a color match, just add your request before you send us your quote or give us a call at 778-565-4970 to discuss pricing.